CollaFibR®

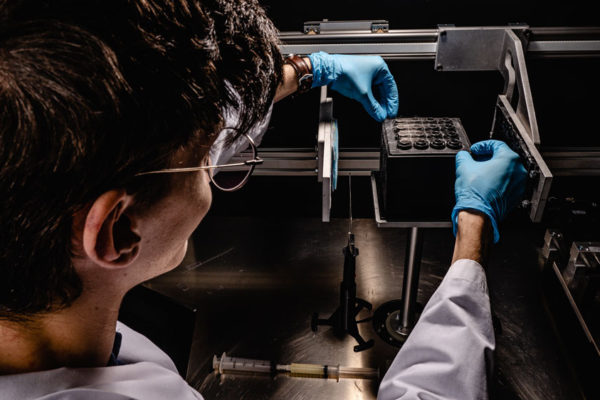

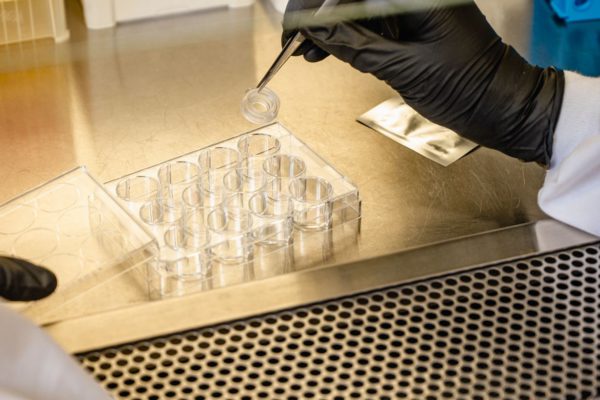

Collagen fibers produced using our patented dry-spinning technology that replicate the biomechanical and biochemical properties of natural collagen structures. With a fully automated manufacturing system, we are the first to produce collagen fibers at commercial scales for a variety of tissue engineering applications, including additives for 3D bioprinting and hydrogels, and cellular scaffolds for 2D and 3D cell and tissue culture.

Press Releases

November 14, 2024